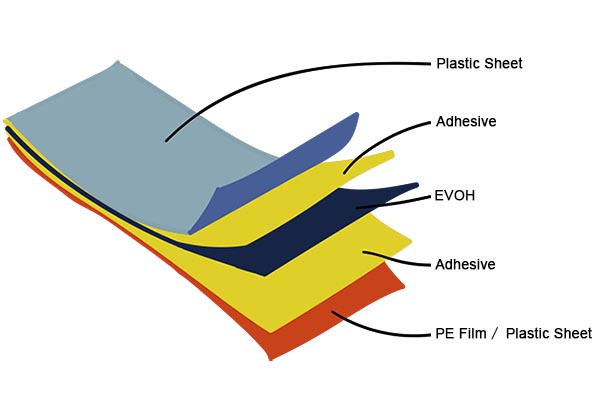

Okokuqala, ii-multilayer co-extrusionukumelana ne-diaphragm yifilimu yeplastiki.Kwintsimi yeemveliso zeplastiki, ngokuqhelekileyo sibhekisela kwiimveliso zeplastiki ezisicaba ezinobukhulu obungaphantsi kwe-0.2 mm njengeefilimu zeplastiki, ezo zinobukhulu obuphakathi kwe-0.2 kunye ne-0.7 mm njengamaphepha eplastiki kunye nezo zinobukhulu obungaphezu kwe-0.7 mm njengeepleyiti.I-diaphragm yokumelana ne-multilayer co-extrusion iya kuba nomsebenzi othile wesithintelo segesi.Umqobo apha ubhekiselele kwisakhono sokukhusela seemveliso zeplastiki (izikhongozeli, iifilimu) ngokuchasene neegesi ezincinci zemolekyuli kunye nevumba.Ngokuqhelekileyo sisebenzisa i-gas permeability ukulinganisa ukufikeleleka kweemveliso zeplastiki.I-PE, i-PP kunye nezinye iiplastiki eziqhelekileyo zinexabiso elikhulu lokungena kwegesi, oko kukuthi, i-gas permeability ihlwempuzekileyo, ngelixa i-PA, i-PVDC, i-EVOH kunye nezinye izinto ze-resin zinexabiso eliphantsi kakhulu lokungena kwegesi kuneeplastiki eziqhelekileyo, kwaye i-gas permeability ilungile.Ke ngoko, siqhele ukubiza iifilimu ye-multilayer coextrusioniqulethe ubuncinane enye imathiriyeli ye-resin ye-PA, PVDC kunye ne-EVOH njenge-multilayer coextrusion resistance diaphragm.I-PE, i-PA, i-TIE, i-EVOH kunye nezinye ii-resin zingasetyenziselwa ukupakishwa kwe-vacuum yeemveliso zobisi, i-jam, iimveliso zenyama, njl.

Iifilimu ezininzi ezidityanisiweyoubukhulu becala amkele ABCBA5 umaleko symmetrical isakhiwo, kunye PA okanye EVOH njengomaleko umqobo kunye nepolyethylene njengomaleko itywina thermal.I-resin enamathelayo isetyenziselwa ukwahlula umaleko womqobo ongaqhagamshelwanga kunye ne-thermal seal layer.I-PA okanye i-EVOH ivakalelwa kakhulu kumswakama, ikhuselwe ngumaleko we-polyethylene, kunye nokusebenza kwayo okugqwesileyo komqobo we-oksijini kuphuhliswe ngokupheleleyo.Ngokubanzi, ubume beifilimu ye-multilayer co-extrudedkuxhomekeke kwiimfuno zokusebenza zefilimu.Kwisiseko sokuhlangabezana neemfuno zenkqubo, ukudityaniswa kweepolymers ezahlukeneyo kunokuhlangabezana neemfuno ezisebenzayo zezinto zokupakisha ezifana nomqobo, ukutywinwa kobushushu, amandla omzimba, ukuhlatywa kwe-thermal, ukulungelelaniswa kokusingqongileyo, iimpawu zokusetyenzwa kwesibini kunye nokwandiswa kokugcinwa kunye nobomi beshelufu.Ukususela kumbono weemfuno zokusebenza, ukudibanisa kweepolymers ezintlanu zanele.Nangona kunjalo,ifilimu edibeneyo edibeneyokunye neeleya ezisixhenxe, ezilithoba, ezilishumi elinanye okanye ngaphezulu zisetyenzisiwe kwimarike eyenza ibe yintsingiselo kwaye iphuhlise ngokukhawuleza.Uyilo loyilo lwefilimu edibeneyo edibeneyo lufuneka ngokuthe ngcembe ukufezekisa imeko efanelekileyo yokudibanisa umsebenzi, iteknoloji, iindleko, ukukhuselwa kokusingqongileyo, ukhuseleko kunye nokuqhutyelwa kwesibini.

1. Ukuthelekisa iindleko

Ukusebenzisa iipolima ezinexabiso eliphantsi kumphezulu endaweni yeepolima ezibizayo kunokunciphisa iindleko zeemveliso kwaye kunomsebenzi wokutywina ubushushu kunye nokumelana nokufuma okuphezulu kweepolima ze-ionic chain.Kwizinto eziphathekayo ezinomqobo ofanayo kunye ne-heat-seal-ability 7-layer co-extrusion evuthelweyo ifilimu inoqoqosho ngakumbi kunefilimu ye-5-layer.

2. Umqobo

Ukusebenzisa iipolymer ezimbini ezahlukeneyo endaweni yepolymer enye kumaleko wesithintelo kunokuphucula kakhulu ipropathi yomqobo.Ngokomzekelo, udibaniso lwe-EVOH umaleko kunye nezinto eziqhelekileyo zenylon azikwazi ukugcina ukungena kwe-PA kuphela, kodwa nokwandisa amandla e-EVOH kunye nokuphucula ukuchasana nokuqhekeka kwe-EVOH ngenxa yokuba i-EVOH layer ifakwe phakathi kweengqimba ezimbini ze-PA amine, eyenza ukuba ifilimu enomqobo ophezulu, ngelixa ifilimu ye-five-layer co-extrusion ayinakufezekiswa.Ukunyuka kweendleko zokongeza i-EVOH kunokongezwa kusetyenziso olupheleleyo lwesakhiwo.Izinga lokuhanjiswa kwe-oksijini yefilimu edibeneyo ye-five-layer co-extruded kunye ne-20% yesakhiwo se-PA yiyunithi ye-3.5, kodwa phantsi kweemeko ezifanayo, izinga lokudluliselwa kwe-EVOH elongezelelweyo kwifilimu ye-seven-layer yi-0.13 units.

3. Ukuxhathisa i-crack

Iipropati ze-PA co-extruded films kunye neengqimba ezininzi zingaphuculwa.Ngokomzekelo, ukusetyenziswa kwe-adhesive layer eyongezelelweyo kunokuphucula ukusebenza komqobo wefilimu ngokunyusa umqobo wokuthintela umphunga wamanzi wefilimu.Enye inzuzo efunyenwe ngaxeshanye kukuba inokwenza ifilimu ithambe ngakumbi, ivakale kakuhle kwaye ibe nokuxhathisa okulungileyo kokuqhekeka.

Ngenkqubela phambili eqhubekayo yetekhnoloji ye-polymer synthesis, iipolymer ezintsha ezineempawu ezizodwa zomzimba kunye nezoomatshini zinokusetyenziswa ngokubanzi ukuhlangabezana neemfuno zokupakisha.Umsebenzi kunye nolwakhiwo lweifilimu edibeneyo ehlanganisiweyo ehlanganisiweyo ye-multilayeriya kuba nokuguquguquka okukhulu kunye noqoqosho.Ngokusetyenziswa kunye nokuphuculwa kwezixhobo zokubumba kunye nethekhnoloji, kudityaniswa noyilo olulodwa nolusebenzayo lwesakhiwo esiyintlanganisela, abavelisi befilimu baya kuba nendima yoguquko ekusukeleni nasekucingeni indlela yeengqikelelo zokwahluka kwemisebenzi yokupakisha, uhlengahlengiso lwesakhiwo sokupakisha, kunye ukwandiswa kweenzuzo zokupakisha.

Ixesha lokuposa: Apr-17-2023